Success stories from practice

Gearbox refurbishment instead of new purchase – why spend more money than necessary?

The gearing parts of a gearbox are subject to natural wear, especially on the shift wheels and pinions. Abrasion on the tooth flanks as well as breakouts and other contamination in the gearbox oil, but also inadequate oil wetting during the start-up phase can significantly accelerate the wear process. The result is usually a drive/manual gearbox that functions poorly or no longer functions at all, which can lead to unplanned production downtimes and failures.

Increasing efficiency in the biogas shredder – research results from the Montanuniversität Leoben

Biogas substrates are often shredded using cross-flow shredders before fermentation in order to achieve a better gas yield. But the tools and linings of these shredders are subject to significant wear and tear from impact and friction.

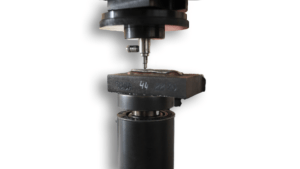

How is a wear lining actually created?

DURAPARTS supplies linings made of DURAPLATES for a wide range of industries and machines in the shredding and mixing sectors. Since I am repeatedly asked how the parts are made and what the technology behind them is, here is a short excursion into our production:

Why are there cracks in our hard faced plates and why are they not damaging to quality?

I’m often asked why there are cracks in our wear plates and whether these don’t lead to faster

Why is the hardness of a wear layer not the only decisive factor for its service life?

I am often asked how hard the components I make are. The question is of course legitimate, as

What we mean by individual wear protection

What is individual wear protection and why does individual protection not automatically have to be more expensive? Especially

Replicating machine parts, even without drawings.

Keeping old machines and systems in operation not only conserves resources, but also usually makes economic sense. Sometimes,

Innovative hard faced plate for long-lasting agricultural equipment

“When I first delivered it, I was put off by the cracks in the components and I never thought that the parts would last long. After 4 years the parts still look like new, simply incredible.” ~Erich Engelbrecht – farmer in Lower Austria

Optimization of screw conveyors for wood-fired power plants.

“You’re welcome to come over for a coffee, but we don’t need any new components yet. Your snails still look like new after 3 years. “ ~ Lukas Hampel – Operations Manager HHKW Hollabrunn