Refurbish instead of investing

The original manufacturers of a manual transmission in an old production plant often no longer exist or are pushing for a new transmission to be purchased, even if refurbishment may be the more sensible solution in economic terms.

The advantages of refurbishing a transmission for the plant operator are obvious:

– Significant cost savings compared to purchasing a new transmission, as only what is necessary is repaired/replaced

– Shorter downtimes, as repairs are quicker than making a new one

– Sustainable use of resources, as less material has to be disposed of

– Elimination of necessary adaptation work, as the housing and thus the interfaces are not changed

– Use of value-added opportunities through optimization during refurbishment

Gearbox parts and complete refurbishments from a single source

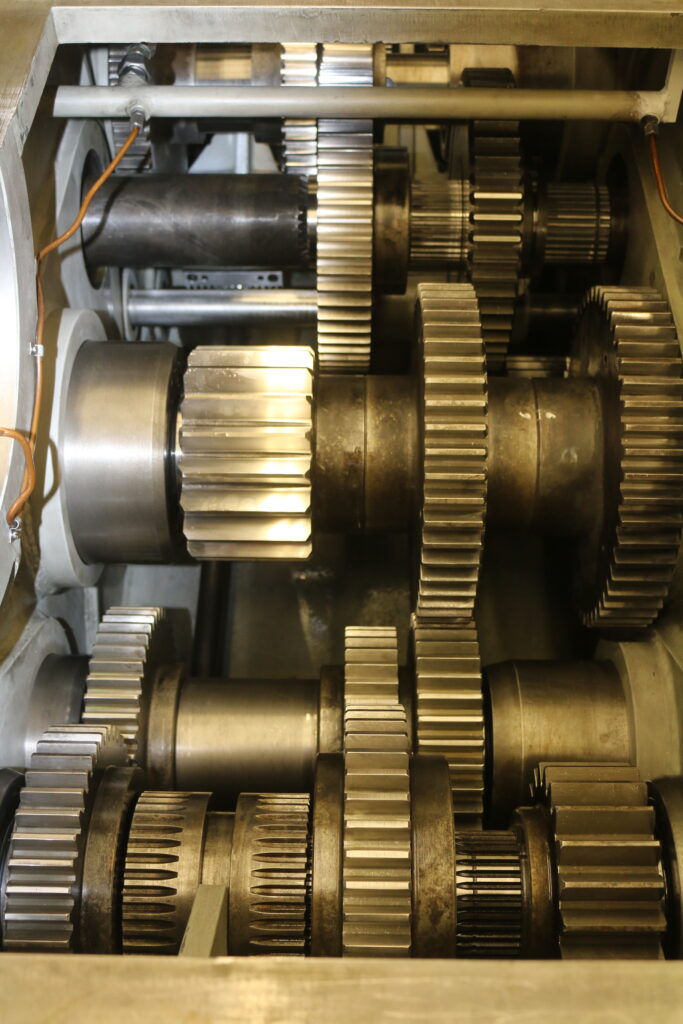

DURAPARTS not only offers short-term reproduction and refurbishment of gearbox parts but also refurbishes every type of drive/manual gearbox together with its partners – all of whom are established gearbox specialists – individually and tailored to the level of wear.

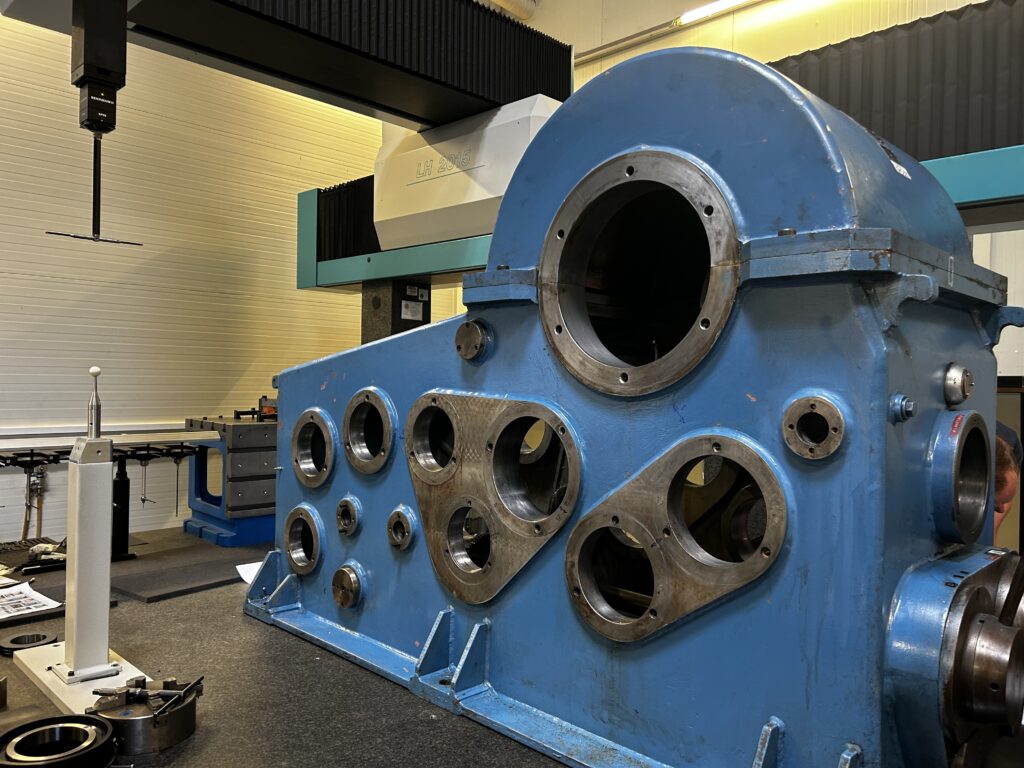

To do this, our specialists determine the need for refurbishment by means of a visual inspection (also on site) and measurement of the housing and the individual parts and create an individual refurbishment concept. After approval by the customer, we re-engineer the gearbox parts, carry out any optimizations and refurbish or remanufacture the individual parts, replace all bearings and standard parts and carry out a load-free test run with the customer after assembly. We also offer on-site disassembly and assembly – in cooperation with the company’s own maintenance technicians if required.

Everything from a single source, just as DURAPARTS customers are already used to from all other areas of our work.

In the transmission project presented, the customer saved almost 60% in direct costs and around €25,000 in necessary adaptation work.

Conclusion

Gearbox refurbishments offer numerous advantages over purchasing a new one. They are cost-effective, sustainable, timesaving and allow for individual adjustments. Companies that opt for refurbishment not only benefit economically, but also actively contribute to conserving resources.

So, before you invest in a new gearbox, it is worth checking the possibility of refurbishment. In many cases, it is the smarter and more sustainable choice.